Sewing Denim like a Pro and, generally speaking, thick or multilayered fabrics.

Tips useful before you start sewing denim (and thick fabrics):

Before everything, please always pre-wash your denim fabric: often it will shrink and, being a dark color dyed cotton fabric, it usually discards some color too (put some vinegar in your rinse water or, better, leave it soak a whole night in warm water plus a cup of white vinegar… it can help fixing pigments and discarding exceeding).

Not to forget that, during warping, denim is being glued with chemicals (like any other fabric): pre-washing will soften it just a tad, making it easier to manage while sewing it.

Just because I think it’s better staying on the safe side, you can choose pre-washing your denim fabric twice (just as I do)… because sometimes one isn’t enough!

Always use SHARP scissors or new blade on your rotary cutter; better cut a layer at a time, you’ll hands will thank you!

If your denim frays a lot, better zig-zag or serge raw edges right after cutting out pattern pieces, before even starting to assemble:

Sewing tips for sewing denim (and thick fabrics):

Always use a specific denim needle: Schmetz (my favorite brand) are the ones with yellow/blue code. They’re sharper and sturdier than universal ones. As usual, choose a bigger number for thicker fabrics ( or multi layer seams, like on flat felled seams) and vice-versa

Sometimes denim can stretch while you sew it: the trick is holding it firmly in front and back of your needle, while sewing, without pulling it at all! This should prevent any unwanted stretch. If it wasn’t enough, try lowering your foot pressure (if you’re so lucky of having this adjustable setting) and or try a teflon foot (like the one for vinyl) that will help fabric feed smoothly without (or with less) friction.

Another solution can be a walking foot, that, eventually, can help your top layers to feed over your sewing foot at the same time of the lower layers, right above the feed dogs. This is mine, a really cheap-o one! Let me say that I love it… really useful! I’d certainly suggest you to try a Walking Foot you too!

Separate seam allowances pressing them open whenever you can, especially if you need to sew across the same seam, to reduce the bulk.

If you have two paired two seam allowances meeting (think crotch seam), try to offset them!

Go slowly, sometimes you’d better turn by hand the wheel to pass over thicker layers of fabric (so you won’t damage your needle and machine too!)

Raise the presser foot higher: yes, even if you thought your presser foot can’t go higher then its high position, it can!

…and this is higher! Just pull it with your finger (and ignore all those wrinkles on my finger, it looks like I have 90 years, but I haven’t!)

If you have this setting (in my sewing machine I don’t) lowering the foot pressure could help (but remember of repositioning the knob before sewing again medium or lightweight fabrics)

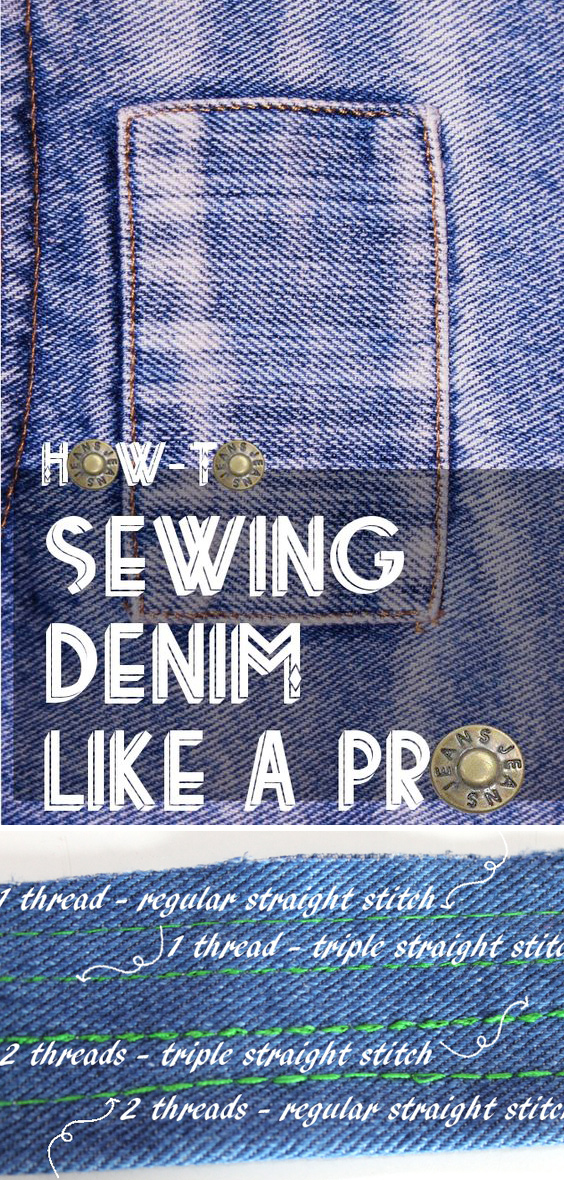

Let’s talk about topstitching: I like the look of a Heavy Duty thread or, better, of a shining silk thread in a contrasting color; as always, when sewing thick fabrics, use a longer stitch length (a 3.5 or 4 works and looks good to me but, as usual, try and practice on scraps, especially topstitching and buttonholes). If you’re in a hurry and don’t have any thick thread in hands, you can always wind a bobbin with your regular thread, slap it into the second spool hanger…

… make your two threads share the same path for a while…

…then thread them trough your needle eye together!

Can you see the difference?

So much bolder with double regular thread, even better using a triple straight stitch!

As usual, your password has to be: practice with scraps and see what you like best!

Just thinking… a decorative seam using those thicker contrasting threads (or a double regular thread) should look really good on denim: think pink thread on dark blue denim, or lime green thread on black jeans! A gorgeous touch to any so-and-so project!

Sometimes, when you start sewing a bulk fabric (like multiple layers of denim), it could happen to you of not lowering the presser foot, because the foot is already touching the fabric (but tension disks and feed dogs aren’t engaged)… Believe me if I say that it “could” happen ;) it’s one of those blonde moments!

Luckily it’s an easily fixable mistake (just go back, rip that seam and re-sew it lowering the presser foot, this time)!

An edgestitching foot is an interesting gadget to add to your (and mine, since I don’t have it… by now!) sewing arsenal if you plan to topstitch a lot: it’s really useful on thicker fabrics on top of all, because it helps following exactly the fold/edge.

Start sewing holding both thread tails in your hand, without pulling them but firmly, like if you were sewing a sheer or a light weight knit: it will help avoiding bird nests.

Other little trick: use some tear away stabilizer (or that thin see-through tissue paper you find on shoe boxes, if you’re frugal like me – I use that one that comes in swimwear packages, working in a swimming pool) to be put on top and/or right above the feed dogs.

Use stronger, thicker heavy-duty pins or, better, Clover Wonder Clips

I use a multilayered Thick-y fabric to start and finish bulk seams (Dritz has created a similar fancy gadget called Jean-A-Ma-Jig, for the lazy sewists: it costs nearly nothing, really affordable and perfect for all those sewing gadget hoarders outside there… yes, I know you like these things… )

Look what happens if you simply start sewing without using anything: the foot is at an angle and the needle will likely break:

Enter: The Thick-y:

Simply place it right before your thick fabric, helping your (machine’s) foot stay horizontal…

When you reach the end of the seam, put it right at the end of the fabric:

After sewn denim (and thick fabrics):

Press seams well, using a lot of steam… and eventually use a rubber hammer or a Meat Pounder!

Reduce bulk trimming seam allowances, clipping curves and mitering corners.

No comments